Pipe Closures

What are Pipe Closures

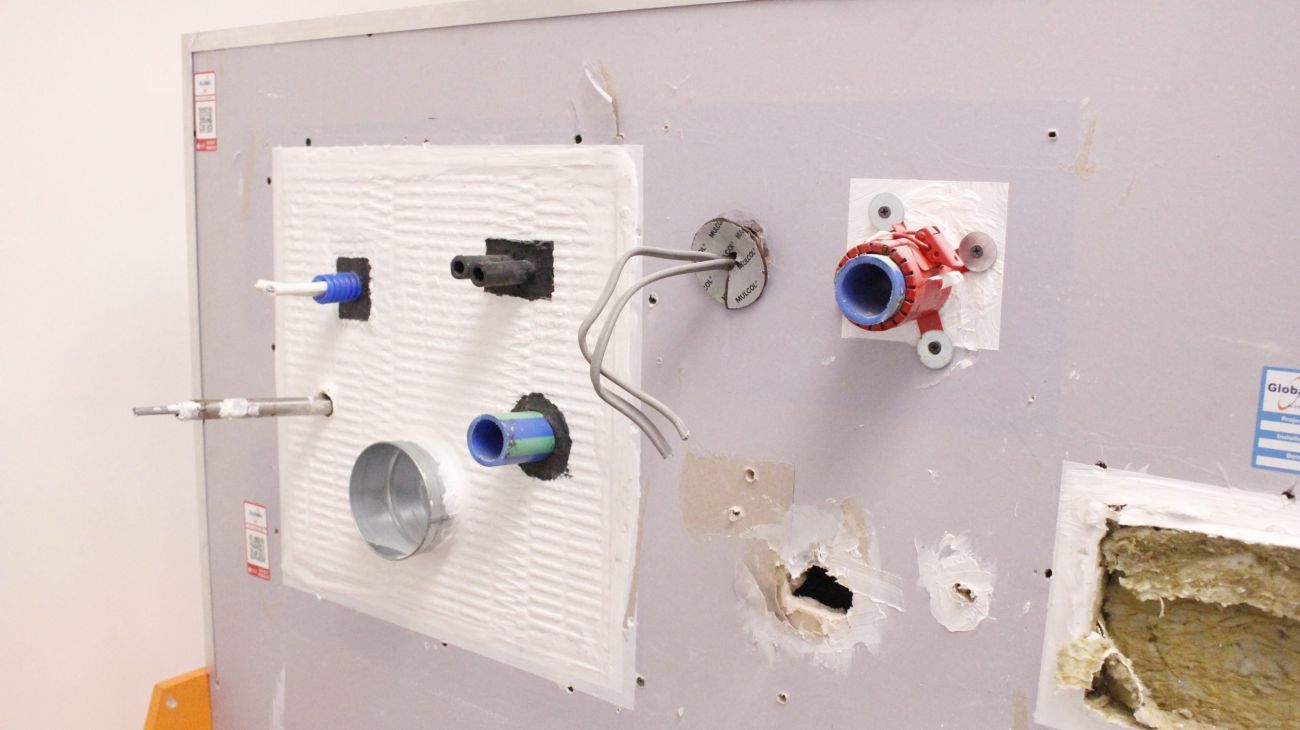

Pipe closures are designed to preserve the integrity of a fire resistant compartment where various cross link plastic pipes (PEX), plastic pipes, plastic trunking, steel pipes with insulation or plastic pipes with insulation pass through floors or walls. Unlike metal or cable service penetrations, these service penetrations soften and collapse under heating, therefore, some means of preventing the passage of fire is required. This is achieved by closing across the void created when the pipe collapses. There are variations in design of pipe closures and the four principal methods of pipe closure are pipe collars, pipe wraps, Insulated Fire Sleeves, and high pressure exerting sealants. All systems contain an intumescent compound which expands on exposure to fire, rapidly exerting pressure upon the pipe or insulation. The service penetrations, which will have softened due to the heat, collapse under this pressure creating a constriction. Some pipe closures incorporate a mechanical device which may or may not include an intumescent compound. Pipe collars incorporate an outer casing which acts as a restraint for the intumescent material, enabling the collar to be either surface fixed to the separating element or incorporated within it. Pipe wraps have no casing and hence must be located within the separating element, which acts as a restraint for the intumescent. Insulated fire sleeves have the intumescent material embedded within the insulation. High pressure exerting sealant contain the same intumescent compound but in a paste format that cures on exposure to air.

Areas of Use

Pipe collars, pipe wraps, insulated fire sleeves and high pressure exerting sealants can be used where plastic pipes (PEX), plastic trunking, steel pipes with insulation or plastic pipes with insulation pass through fire resistant elements such as floors or walls.

Installation: Pipe wraps

Pipe wraps are fitted into an oversize hole in the separating element, surrounding the pipe. If there is a fire risk on both sides of a compartment wall or floor two wraps may be required. The position of the pipe wrap within the wall or floor can be critical e.g. many pipe wraps for soil pipes passing through floors need to be positioned at the bottom of the opening in the floor to activate properly. Similarly, a pipe wrap tested in a rigid wall may not work when tested in a flexible wall without suitable framing out. Specifiers and installers should check that the supporting fire test evidence is applicable for the end use application envisaged.

Installation: Pipe collars

Installation: Insulated Fire Sleeves

Insulated fire sleeves may be installed on pipes that pass directly through an element of construction purely as a pipe closure, or where an insulated combustible or non-combustible pipe passes through an element of construction and there is a requirement to maintain an insulation layer. In the first instance, the requirement will be to ensure the opening and annular space between the outer wall of the pipe and the substrate is of the correct dimensions to enable the sleeve to fit through around the pipe and protrude each side to the appropriate length. A single bead of acrylic sealant will be required around the pipe where it meets the wall to provide a cold smoke seal. Where a pipe is insulated, it is simply a case of removing the appropriate length of insulation and replacing it with the fire sleeve which will then be joined back to the original insulation with an aluminium foil tape.

Installation: High Pressure Exerting Sealants

High Pressure Exerting Sealants are installed into an oversize aperture in the separating element, surrounding the penetrating service. If there is a fire risk on both sides of a compartment wall or floor, HPE sealant may be required on both sides. The high-pressure exerting sealant is installed to a prescribed annular gap to a predetermined depth between the service penetration and the constructing element. The backing material for these sealants should be checked before use to ensure they are approved. High-pressure exerting sealants tested in a rigid wall may not work when tested in a flexible wall without suitable framing out. Specifiers and installers should check that the supporting fire test evidence is applicable for the end use application envisaged.

Cavity Barriers

When constructing a building with voids and cavities, it’s crucial to incorporate cavity barriers to effectively halt the unseen fire spread within concealed cavities.

Fire Compartmentation

Compartmentation plays a vital role in building fire safety by dividing structures into distinct sections that can contain and control the spread of fire.

Fire Dampers

Fire dampers are crucial for creating barriers that resist the spread of fire and smoke through ductwork systems.